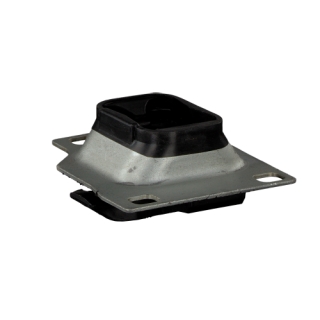

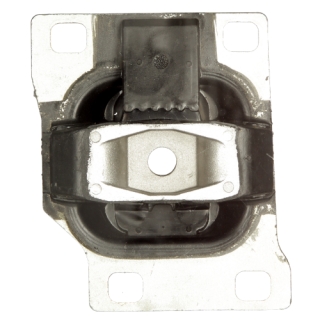

Product Information

- Specific rubber compound reliability prevents vibrations

- Optimal fitting accuracy for easier repairs

- Strict quality standards

- Compliance with the requirements of vehicle manufacturers

Vehicle Repairs. We've Got What It Takes.

Perfectly functioning engine mountings are required for the safe fastening of the drivetrain in the engine compartment and they also ensure a comfortable ride thanks to optimal vibration damping.

Rubber-to-metal parts are used as elastic joints between chassis and body, especially in multi-link axle designs. They absorb the vibrations generated by the road surface and drive units while the vehicle is in motion thus making a significant contribution to increasing driving comfort and noise insulation. In addition, they ensure driving safety by improving steering behaviour and driving stability on uneven road surfaces as well as braking and avoidance manoeuvers.

If the engine mounting is defective or worn, engine vibrations are not - or only partially - damped and are transmitted to the body instead. Unpleasant noises in the interior are the result. In extreme cases, a worn out engine mounting can no longer hold the engine in position sufficiently. If the engine then touches the body under load, this not only causes loud noises in the interior, it can also damage the engine attachments.

In the rubber-to-metal sector, febi offers one of the widest ranges in the Independent Aftermarket - naturally in OE matching quality. This also includes mountings for manual and automatic transmissions.

Quality by Conviction

Engine mountings dampen vibrations and reduce vibrations. They must reliably absorb the resulting motor torques during load changes. Engine mountings from febi are therefore intensively tested. Our quality management tests the motor mountings offered for various requirements and loads, e.g. accuracy of fit, dimensional accuracy, material quality, and tensile strength.

Transmission mounts dampen vibrations and reduce vibrations. At the same time, they must give the transmission the necessary stability so that the torque is reliably transmitted from the engine to the wheels. Transmission mounts from febi are therefore intensively tested.

In the engine mount sector, febi is one of the leading suppliers in the Independent Aftermarket. Our range exclusively includes engine mountings that dampen vibrations as best as possible and meet the manufacturers' approval requirements.

Our quality management tests the offered transmission mounts for various requirements and loads, e.g. accuracy of fit, dimensional accuracy, material quality, and tensile strength.

The Right (Rubber) Compound

The elastomer materials used in the manufacturing of rubber-to-metal parts are precisely matched to the technical requirements and loads of their specific installation position. febi's product range exclusively includes rubber-to-metal parts whose rubber compounds are also used by the original manufacturers.

Selected Language / Multilanguage

| Suitable to replace | Reference(s) |

|---|---|

| Ford | 1 133 020 | 98AB7M121PB | 1 061 125 | 1 061 131 | 1 066 070 | 1 092 270 | 1 092 271 | 1 092 954 | 1 126 212 | 1 133 019 | 98AB7M121AJ | 98AB7M121AK | 98AB7M121CG | 98AB7M121CH | 98AB7M121NB |